Roast to reveal

Before coffee can be brewed, poured, and enjoyed, it has to be roasted. Green coffee beans in its raw form is not something you’d want to drink. It would probably just taste like grass, chewy and very acidic after taste. Roasting is what transforms them into the aromatic, flavorful beans we grind and brew every day.

Unlocking the flavors of coffee

At this stage of the Bean to Mug blog series, we break it down in much more detail. The roast process. what happens to the bean as the process goes on. The tools used, and what roasters are looking for at every stage.

What Happens During Roasting?

Roasting is both a chemical and physical transformation. Here’s what goes on inside the bean:

- Moisture is removed: Green beans contain 10–12% water. Roasting drives it out.

- Pressure builds inside the bean: As water turns to steam and gases form, the internal pressure increases.

- The bean expands: Beans can swell up to twice their original size.

- Chaff separates: A thin skin (chaff) detaches and falls off during roasting.

- Chemical reactions kick in: The Maillard reaction and caramelization break down sugars and proteins, creating flavor and aroma compounds.

- Oils begin to emerge: Especially in darker roasts, oils move to the bean’s surface.

- Carbon dioxide is formed: About 1–2% CO₂ builds up inside the bean and later degasses after roasting.

Types of Roasters

Roasters are the machines used to apply heat to the beans. The most common types are:

- Drum Roasters – Use a rotating drum heated from below. Great for consistent batch roasting with good control.

- Hot Air Roasters (Fluid Bed) – Beans float on hot air, resulting in a clean, fast roast. Ideal for smaller batches or sample roasting.

- Hybrid Roasters – Combine drum and hot air technology for better control over heat application and airflow.

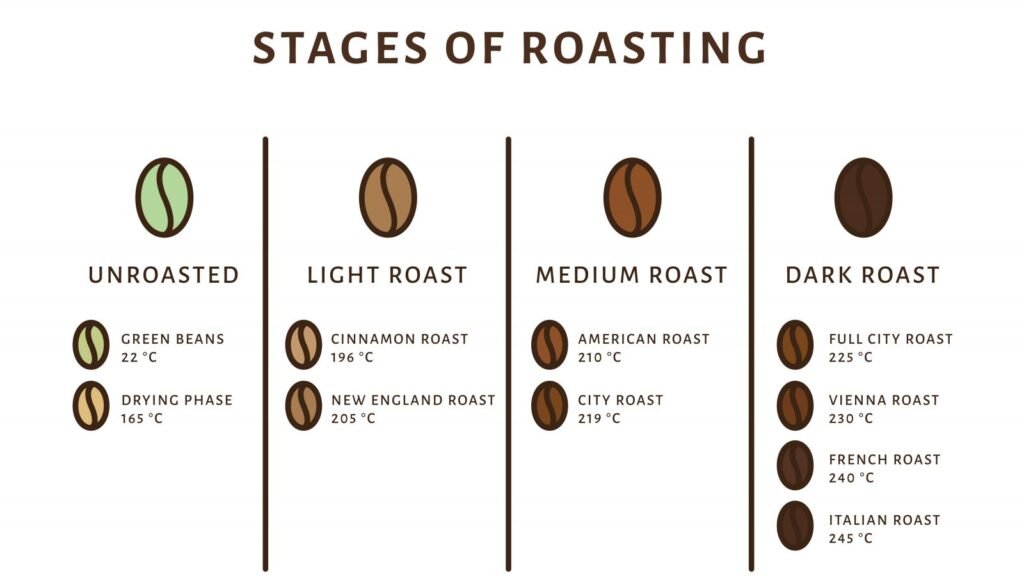

The Roast Stages

Each roast follows a typical curve or timeline. Here’s how it unfolds:

- Charge – Beans are dropped into the roaster at the desired starting temperature.

- Turnaround Point – The bean temperature hits its lowest point before rising.

- Color Change – Beans go from green to yellow to brown. The first signs of aroma appear.

- First Crack – Beans pop audibly as internal pressure releases. Light roasts typically stop here.

- Second Crack – A quieter, more subtle cracking sound. This stage introduces deeper, smokier flavors found in dark roasts.

- Drop – Beans are removed from the heat and cooled quickly to stop roasting.

Roast Profiles

A roast profile is the blueprint of a roast—tracking time, temperature, and changes at each stage. Roasters use profiles to:

- Highlight specific flavors (e.g., fruity acidity or chocolatey body)

- Ensure consistency across batches

- Adjust for bean density, moisture, and origin

Each coffee deserves its own approach, depending on where it was grown, how it was processed, and how it’s going to be brewed.

Roast Time

Typical roast times range from 8 to 16 minutes, depending on:

- Roast level (light, medium, dark)

- Type of roaster

- Bean characteristics

- Desired flavor outcome

Faster roasts bring out brightness and acidity, while slower roasts emphasize sweetness and body.

Once the beans are roasted and rested (usually for 12–72 hours to allow for degassing), they’re ready for the next step: brewing. The final chapter of the journey from bean to mug.

Except if you are someone who prefers to make your own coffee , or just prefers instant coffee ( out of it’s convenience), the Barista at your favorite cafe will be the one who expertly takes the roasted beans, dials in the right recipe, and brewing it to bring out everything the roaster worked to highlight. Water temperature, grind size, dose, and brew time all play a part.

From the farm to the roaster to the barista, each one adds a layer of intention. Enjoy your favorite cup and stay caffeinated!